ARMOUR SOCKS

Capabilities

Design Research

Product Development

Competencies

Research: market, user, anatomy, product

User Studies: field work, focus groups, interviews

Sketching: Hand and Digital, mood board

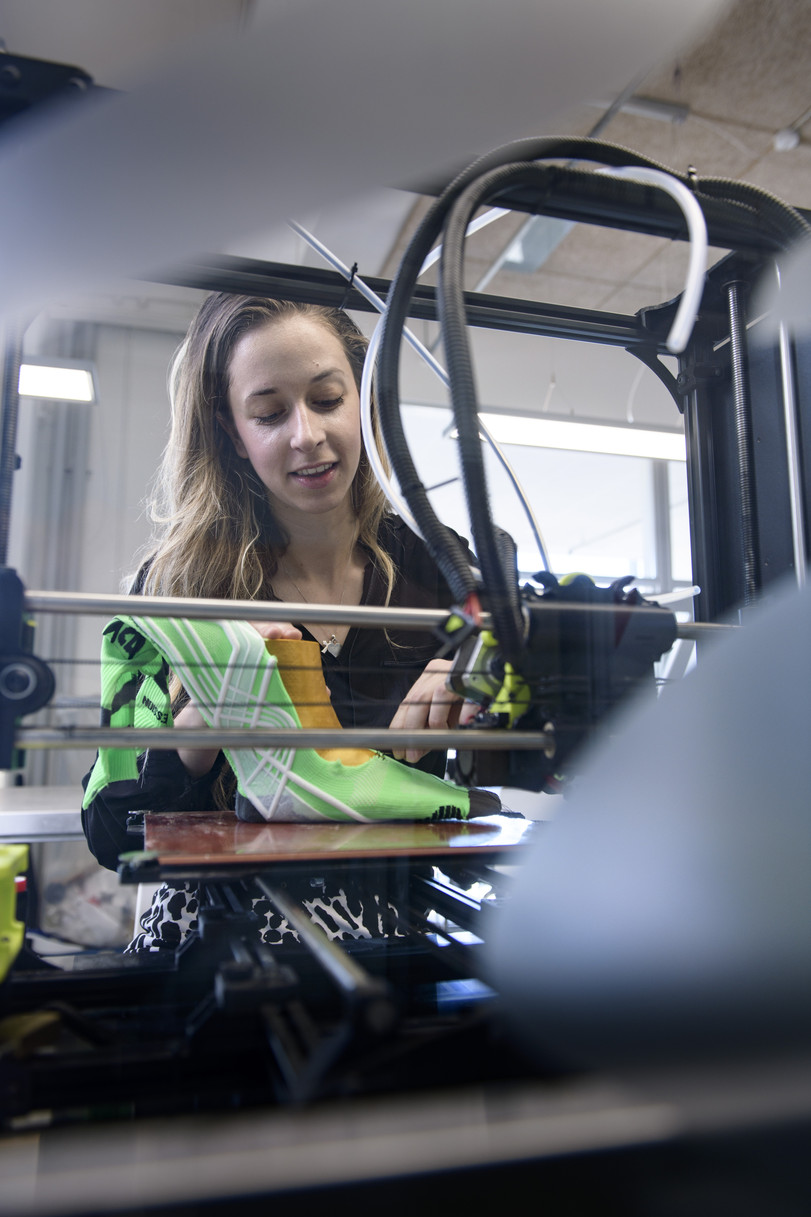

Prototyping: CAD, 3D printing, sewing

Software: Rhino, Keyshot, Photoshop, Illustrator

Collaboration

Aarhus University Hospital

If all athletes are expected to be well-oiled, fine-tuned, machines - then the same level of tailored attention should be demanded of their equipment. However, it’s not.

Ankle sprains are the most common injury among all athletes. The existing equipment, such as ankle braces, are bandaid solutions and rehabilitation is a long term investment that begins after their first sprain.

The projects concept focuses on providing young elite athletes a better way to reduce the risk of ankle sprains. The solution was customized sportswear that utilized additive manufacturing.

Phase 1

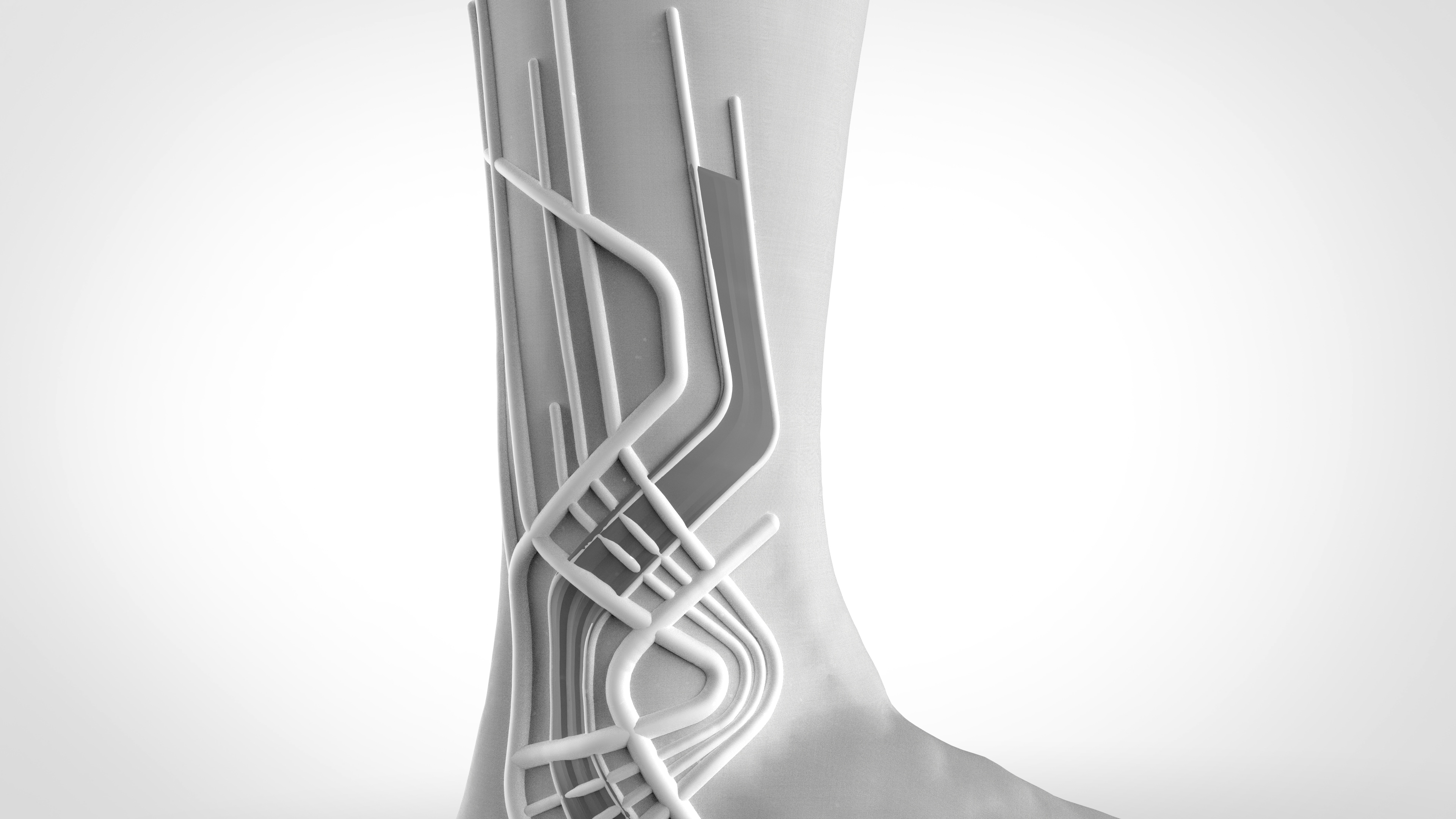

Research & IdeationThe project began with perliminary research, experimentation through 3D printing, and an analysis of existing solutions. I explored different methods, materials, and geometries that can be produced through 3D printing. Then I analyzed existing solutions such as ankle braces and modelled them in Rhino. Finally, I applied the 3D experimentation findings to the modelled existing solutions and 3D printed them.

Phase 2

Concept Development: FunctionThis phase was a focus on the function of the need. The goal was to identify both technical and functional specifications. From the technical side, I took a deeper dive into learning and understanding the ankle anatomy and biomechanics. I identified the the areas of the ankle that required support through research and prototyping. From the functional side, I focused on both market research and the user experience and conducted interviews and surveys with athletes to better understand their needs.

Phase 3

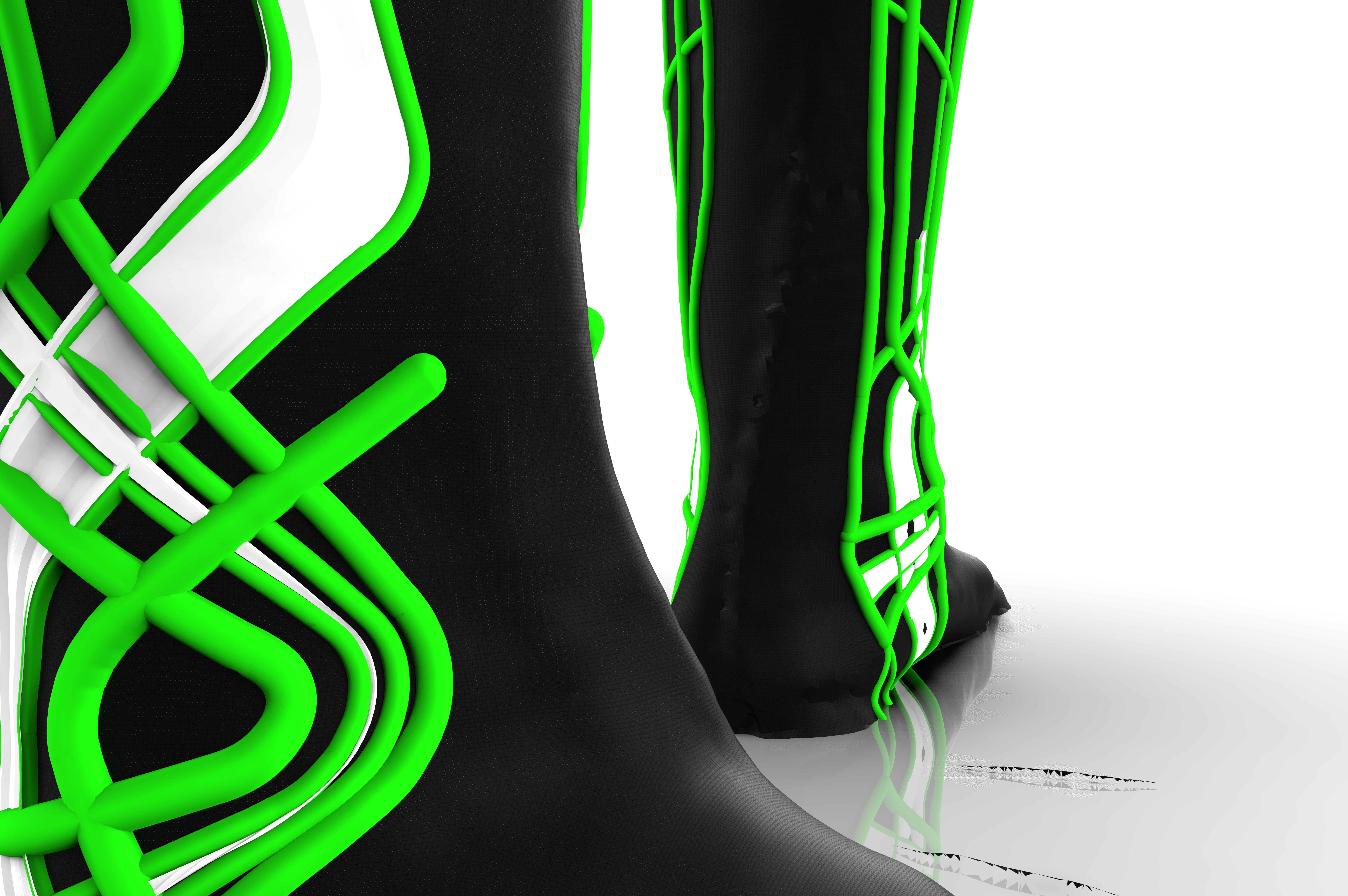

Concept Development: Form & RefineThis phase was a focus on the form. I combined the conclusions of the previous phases and integrating them into a stand-alone concept. This was accomplished with mood boards, clay modeling, 3D printing, hand sketching and digital sketching.

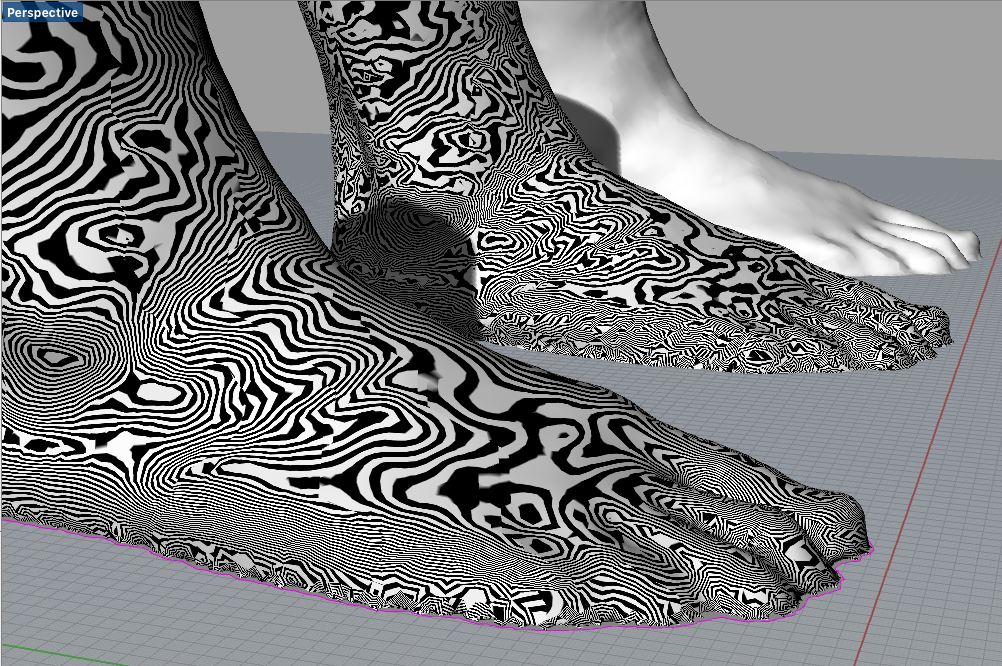

This phase was a focus on adding the final layer: customization. I 3D scanned my ankle and applied the final form. The models were finalized in CAD. I developed numerous prototypes to get to a proof of concept.

Copyright 2023 Elena Stefanac